NJPT Expands Capabilities with 5-Axis Machining: Introducing the Kitamura Supercell-400G

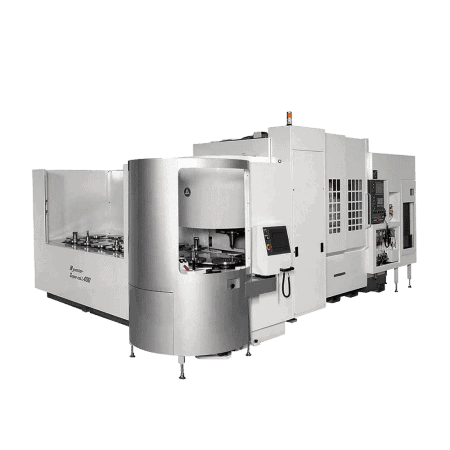

At New Jersey Precision Technologies, Inc. (NJPT), we’re committed to staying at the forefront of precision manufacturing by continuously investing in the latest technology. We’re excited to announce the newest addition to our facilities—the Kitamura Supercell-400G. This 5-axis horizontal machining center is designed to support the efficiency, versatility, and precision to another level at NJPT.

The Kitamura Supercell-400G

With increased capacity, superior accuracy, and unmanned machining, this machine strengthens our ability to support a wide range of industries including aerospace and medical. Whether its tooling, fixtures or production parts, the Kitamura Supercell-400G enhances our ability to meet the most demanding industry standards.

Key Features of the Kitamura Supercell-400G

5-Axis Machining Versatility

In-house 5-axis CNC machining enables NJPT to tackle complex geometries and intricate components easily. The extra flexibility provided by 5-axis machining capabilities means fewer setups, increased precision, and faster production times—perfect for precision-critical industries like aerospace, defense, and medical devices.

Automatic Tool Changer

The automatic tool changer (ATC) is an innovation catalyst for production efficiency. The ATC system is capable of holding up to 200 tools, giving us the ability to handle complex projects which require multiple tools without any added downtime. NJPT operates 24/7, and with the Supercell-400G’s automatic tool changer, the machine is able to continue running unattended. This capability allows for reduced lead times and the ability to have uninterrupted, lights-out production.

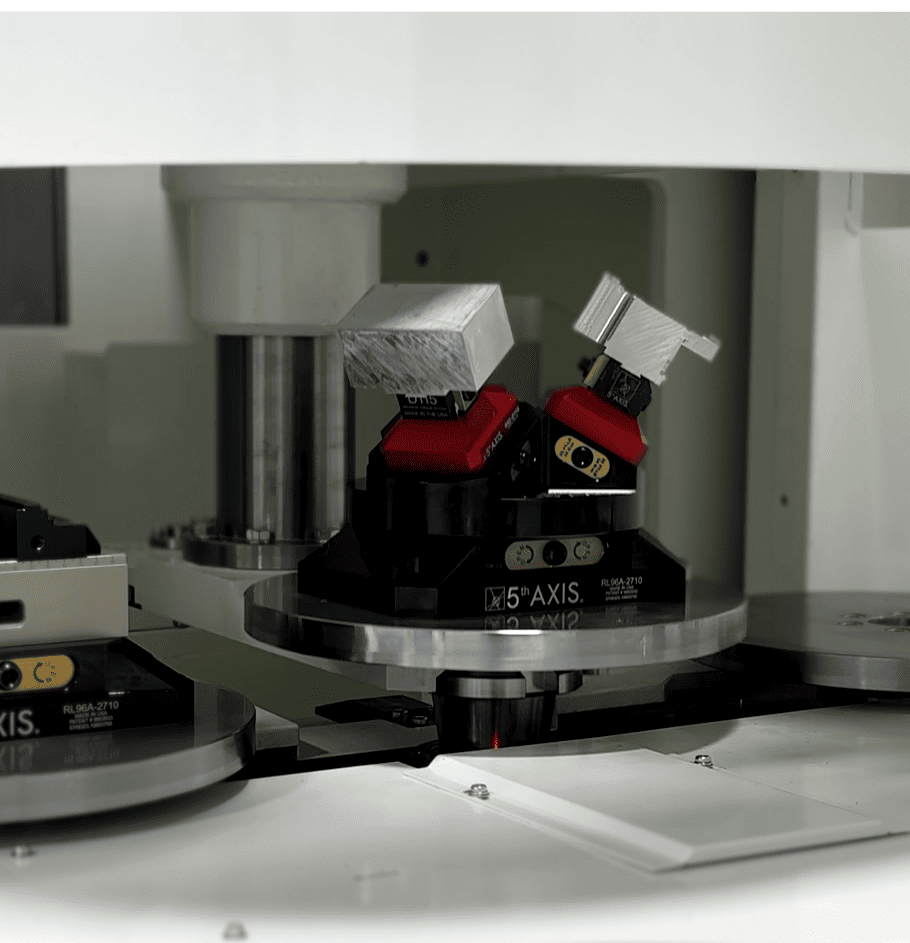

Automatic Pallet Changer system of a Kitamura Supercell-400G, featuring 5-axis workholding for high precision and multi-axis machining

Ultra-High Accuracy & Repeatability

Precision and accuracy are non-negotiable at NJPT. The Kitamura Supercell-400G delivers an impressive positioning accuracy of +/- .000039” full stroke, and a repeatability of +/- .00002”, ensuring that every part remains consistent, with uncompromised precision.

Large Workpiece Capability

The automatic pallet changer holds 20 pallets, each supporting up to 440 lbs and 16” x 16” workpieces. With such a large capacity, this machining-powerhouse can handle a wide range of projects, from small and intricate components, to larger and more complex assemblies. This feature also allows for advance planning to guarantee on-time deliveries.

What This Means for You

Adding the Kitamura Supercell-400G to our machining lineup is not just an investment in technology, but an investment in our customers. With enhanced in-house capabilities, NJPT is better equipped to provide shorter lead times, higher and more consistent accuracy, increased production efficiency and improved versatility to provide for even the most demanding industries.

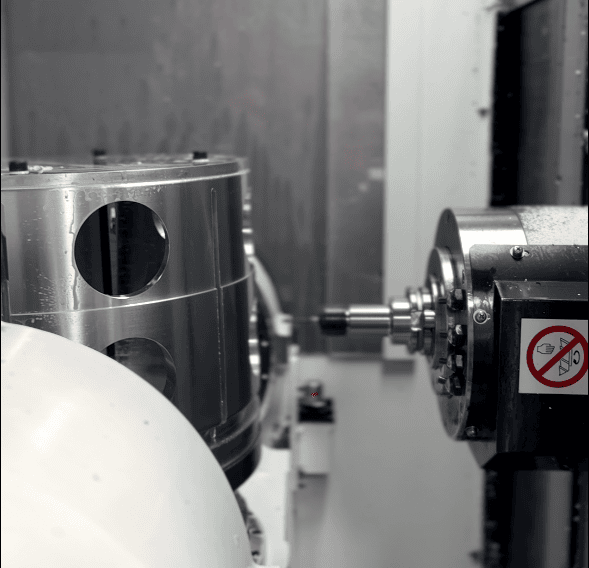

Large round workpiece being milled

From prototyping to full production runs, NJPT is ready to meet your precision manufacturing needs with unbeatable quality and efficiency.

Interested in learning more? Contact sales@njpt.com today for a quote or give us a call at (800) 409-3000.

Our team is here to provide you with precise, high-quality parts and exceptional service. Leave a comment to start a conversation about your project and see how our machining capabilities can help!