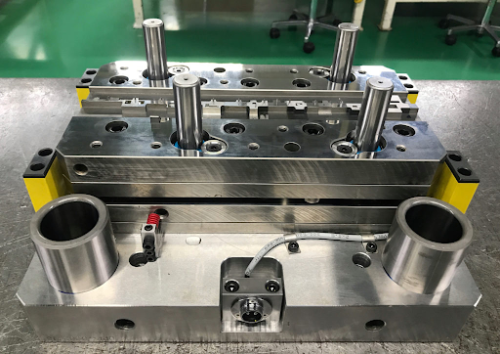

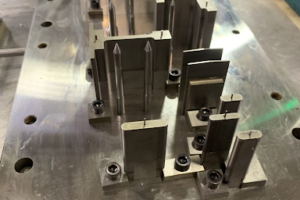

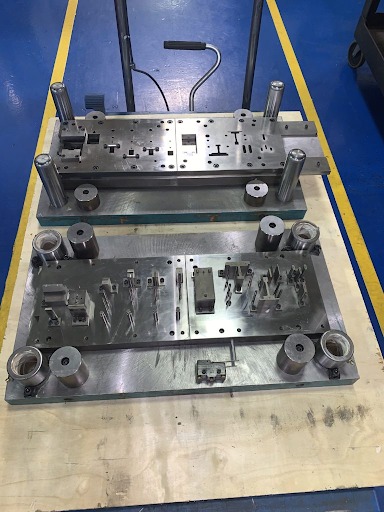

Tool & Die Design and Build

- The Tool and Die profession is alive and well at NJ Precision Technologies. With decades of die design and die building experience, we are well suited to produce, repair or maintain all types of stamping dies for all materials in all industries. Whether or not you need one component or an entire die built, we provide the same attention to detail to provide the support you need. We can help with Wire EDM cutting your supplied die components or manufacture the components with EDM or design & build the entire tool from piece-part-print to stamped product samples. We are not a stamping company but a Wire EDM and tooling company. We are here to help our stamping customers, extruders/fabricators and OEMs to produce their products faster and better in every way. We understand the nuances of die design, construction, maintenance, building and quality requirements and are ideally suited to work on your die requirements.

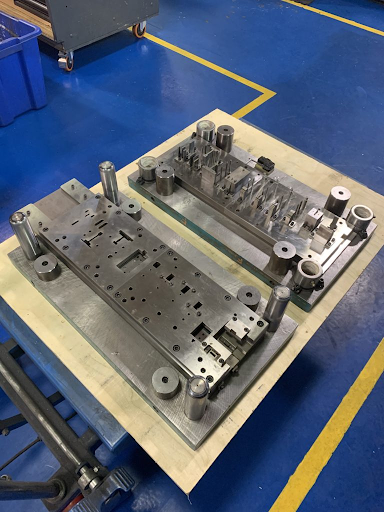

- Our experience ranges from single operation dies to full, multi-station progressive dies and everything in between. Our experienced designers, CNC / EDM technicians and tool & die makers can provide a solution that fits your needs and time frame.

Tool & Die Industry

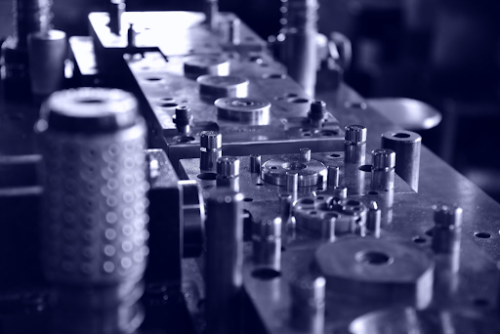

- With less and less tool & die makers working in the industry, new approaches to die design, build & maintenance is required. Many young people are not going to trade schools to learn this and many apprenticeship programs have discontinued their programs. The tool and die makers remaining on the job are retiring and they have few apprentices to train. We have addressed this “Silver-Tsunami” by creating our own TOOL & DIE training program which includes automating many of the traditional tasks with CNC technology and innovative software solutions. We can now design and debug many die designs before any tools are built and minimize the tool & die maker’s time for debug and die try-out. By designing the die with common and standard building blocks, dies can be assembled, tested and maintained faster than ever before. The advantages of our automated approach are numerous and most significantly, allowing your dies to be built on-time and in-specification. Sharpening and die maintenance is more precise and faster than ever before at NJPT. By using our CNC Grinders and State of the art wire EDM machines, the process will also improve the life of the tools.

Tool & Die Industry Capabilities

- Design of new dies

- Building new dies

- Die maintenance, repair and sharpening of your dies

- Replacement components and spare parts of die parts.

- Reverse engineering of die components that have no blueprints or CAD data.

- Dies for forming and cutting: metal, plastic, castings, forgings, paper

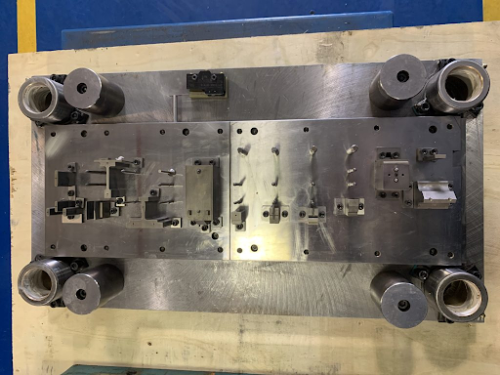

Types of dies to build, repair or maintain:

- Progressive dies (up to 36” long”)

- High speed progressive dies

- Single operation dies

- Compound dies

- Trim dies for die castings

- Form dies

- Pierce and cut-off dies

- In-line dies for plastic extrusions

- Shape dies for trimming, piecing and cut-off of Plastic extrusions

- Shear dies

- Carbide dies

Die components:

- Die sections

- Die inserts

- Spring stripper plates

- Bridge stripper plates

- Guide rails / stock guides

- Back up plates

- Punch holder plates

- Punch holder inserts

- Trim punches, cut-off punches, form punches, cam punches

- Die Shoes, bolsters, adapters

We stock thousands of pounds of material for die components including:

- CPM-10V, CPM 7V, CPM 4V

- D2, A2, 4140, 4340, P20, 420 SS

- Micrograin carbide

- Hardened steel and annealed conditions

NJPT die-design strategy:

- Our tools are designed using software and techniques that optimize the tool quality and speed the manufacturing process.

- Punch & die clearances are very uniform due to wire EDM cutting the dowel pins in the same set up. Improves the life of the tool and reduces sharpening.

- Die set dowel holes in punch holder shoe and die shoe are designed for wire EDM in one assembled set up. This guarantees line-up of upper & lower components.

- Drop-in, field-replaceable components for spare parts or easy repairs.

- Die shoe scrap openings and dowel holes are wire EDM cut to ensure perfect line-up without the risk of transfer-error of any components.

- Design with maintenance in mind. Keeps the tool running more.

NJ Precision Technologies, Inc. can be a valuable source to partner with your stamping operation and existing tool room. We can handle your overflow needs for die building and maintenance. We welcome an initial consultation with your production team, toolroom team or engineering team to discuss what solutions we can offer for your quality or delivery issues. With decades of experience with all types of metal stamping and plastic stamping dies, we can offer ideas and solutions to the most challenging of die problems. We can usually provide a quotation for your die needs in just a few days after receiving your information.