Precision Meets Innovation: NJPT’s Strategic Upgrades with the New Mitsubishi MV1200 Wire EDM

Leave a CommentPrecision Meets Innovation: NJPT’s Strategic Upgrades with the New Mitsubishi MV1200 Wire EDM

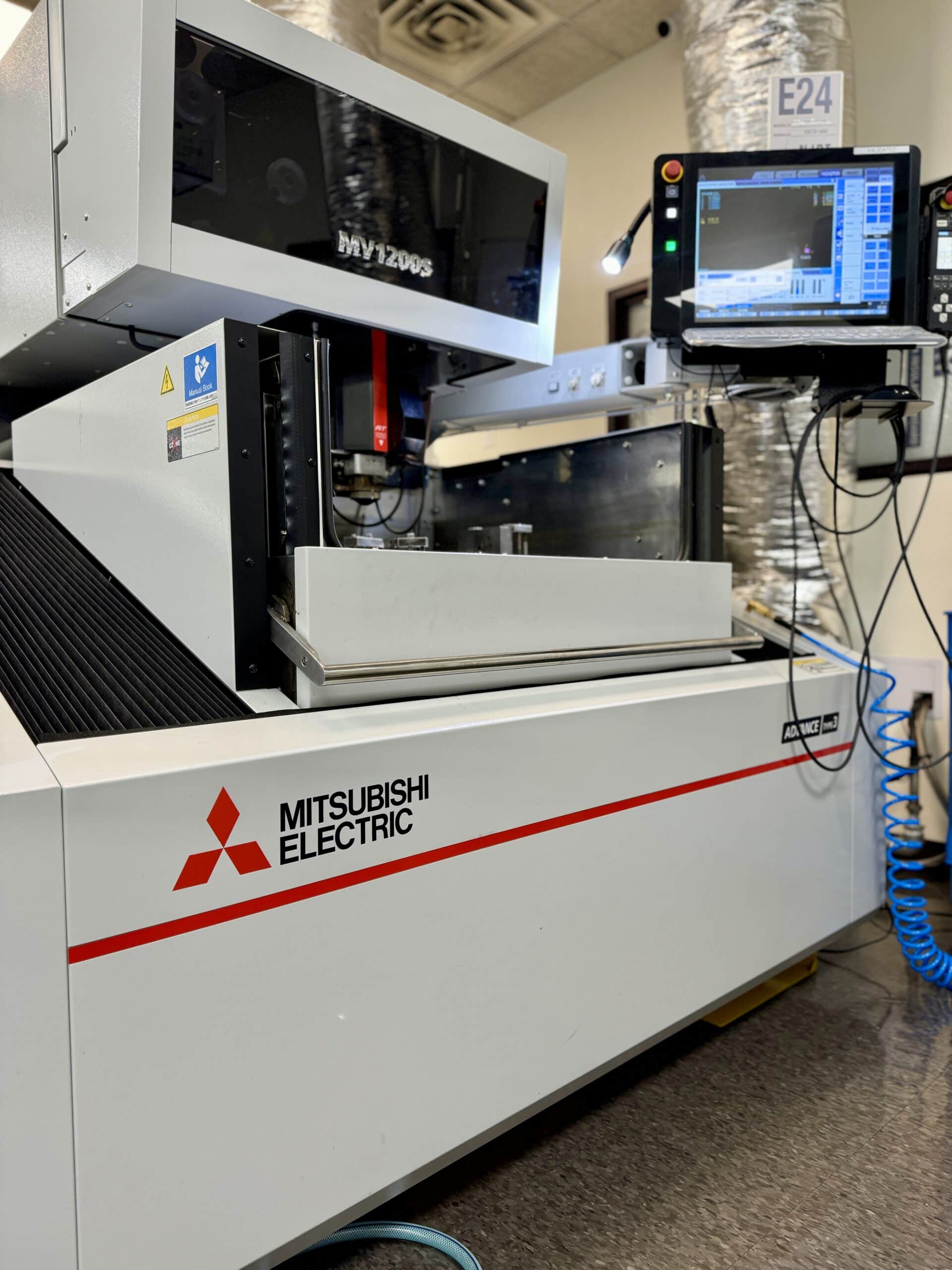

In an industry that is constantly evolving, here at New Jersey Precision Technologies, Inc. (NJPT), we are always looking for ways to improve our methods and provide exceptional services to our clients as the industry leader in precision manufacturing. We are excited to introduce another new wire EDM machine, the MV1200 model, to our large collection of EDM machines. This is just one part of our ambitious three-year strategic plan to upgrade our equipment to the latest technology, ensuring we continue to exceed our customers’ expectations.

What is Wire EDM?

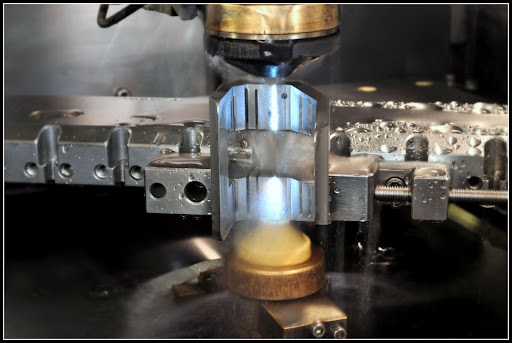

Before we dive in to the perks of a new machine, you may be wondering, what is wire EDM? Wire EDM, or Wire Electrical Discharge Machining, is a precision machining process that utilizes a thin, electrically charged brass wire in deionized water. As the wire nears the conductive workpiece, a spark is generated, creating heat that erodes the material. This allows for precise machining without the mechanical stress often associated with CNC machining. Wire EDM is often preferred for achieving intricate geometries, high tolerances, and excellent surface finishes.

Moving with the Times

The new Mitsubishi MV1200 machines are a testament to our dedication to precision, reliability, and efficiency. These state-of-the-art machines are designed to handle the most complex and demanding projects, providing unparalleled accuracy and consistency. By adding these machines to our existing lineup, we are not only expanding our capacity but also improving our ability to meet tight deliveries without compromising on quality.

Benefits of Electrical Discharge Machining (EDM)

EDM technology brings numerous benefits that exceed those offered by traditional machining methods. With newer EDM machines, they will provide smoother finishes, enhancing the functional quality of the parts. They have the ability to achieve tighter tolerances, consistently meeting the highest standards of accuracy required in the aerospace and medical device industries. With the introduction of these machines, NJPT is poised to overcome these challenges. We provide not only high-quality and precise parts but also the agility and flexibility to quickly and efficiently adapt to our clients’ changing needs.

At NJPT, we are dedicated to staying ahead in the competitive manufacturing industry by taking advantage of advanced technologies. With enhanced quality and precision, faster turnarounds, and state-of-the-art technology, our investment in new machinery shows our commitment to excellence. The addition of these new MV series wire EDM machines is a significant step forward in our mission to provide top-tier manufacturing solutions This proactive approach ensures that we not only meet but exceed our customers’ expectations with on-time deliveries and outstanding customer service. In an industry where precision and reliability are essential, our dedication to continuous improvement and technological innovation sets us apart as a leader in the manufacturing industry. We are excited about the future and the opportunities these new machines will bring.

Stay tuned for more updates as we continue to roll out new equipment and capabilities, all with the aim of serving you better.

Interested in learning more? Contact sales@njpt.com today for a quote or give us a call at (800) 409-3000.

Our team is here to provide you with precise, high-quality parts and exceptional service. Leave a comment to start a conversation about your project and see how our EDM services can help!