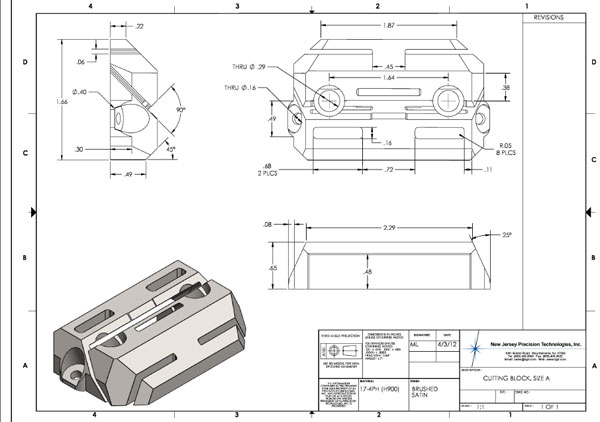

A leading precision surgical instrument manufacturer chose New Jersey Precision Technologies, Inc. for the fabrication of this orthopedic surgical cutting block. Designed for use in knee replacement operations, the cutting block dramatically improves the surgical process by providing a customizable template for each patient. The cutting block with guide slots accommodates an oscillating saw and allows the surgeon to set the precise location, depth, and angle for the required cuts. This eliminates the need to drill into the bone and insert a metal rod to guide the saw blade. The result is a better fitting, smoother functioning, longer lasting joint.

We manufactured 25 cutting blocks in six different sizes utilizing our high precision electrical discharge machining (EDM) and CNC machining capabilities. EDM has several advantages over traditional machining techniques, including the ability to cut hardened metals, hold tight tolerances and machine intricate features with no direct contact between the wire or electrode and the workpiece.

New Jersey Precision Technologies used wire EDM, sinker EDM and hole pop EDM as well as traditional CNC milling to manufacture the cutting blocks, meeting tolerances of ±0.0005” and ±0.25° on some features. Our customer’s specifications also called for a surface finish of 28 RMS for the slot interiors and brushed satin finish for the exterior of the part.

For more information on this project see the table below or contact us directly.