The aerospace and defense industry can be a challenge for manufacturers because of the critical nature of the work. Reliable components are crucial in ensuring safety protocols for operators and equipment. With intricate parts and strict quality standards to meet, aerospace manufacturing requires refined engineering capabilities for a dependable product.

At New Jersey Precision Technologies, Inc., we have spent decades providing high-quality electrical discharge machining (EDM) components and services to our aerospace clients.

Precision in the Tool and Die Industry

Our customers in this industry build or design systems and components for aircraft. Alternatively, our clients work in supporting the industry overall, in sectors such as general aviation and avionics, defense aircraft and carriers, and fixed and rotary wing commercial aircraft.

To support them, we offer wire, sinker, and drilling EDM services. Our state-of-the art Mitsubishi machines provide precision and quality control. We are also ISO 9001 and ISO 13485 certified, guaranteeing our work will meet aerospace regulations.

Spaceflight Industry

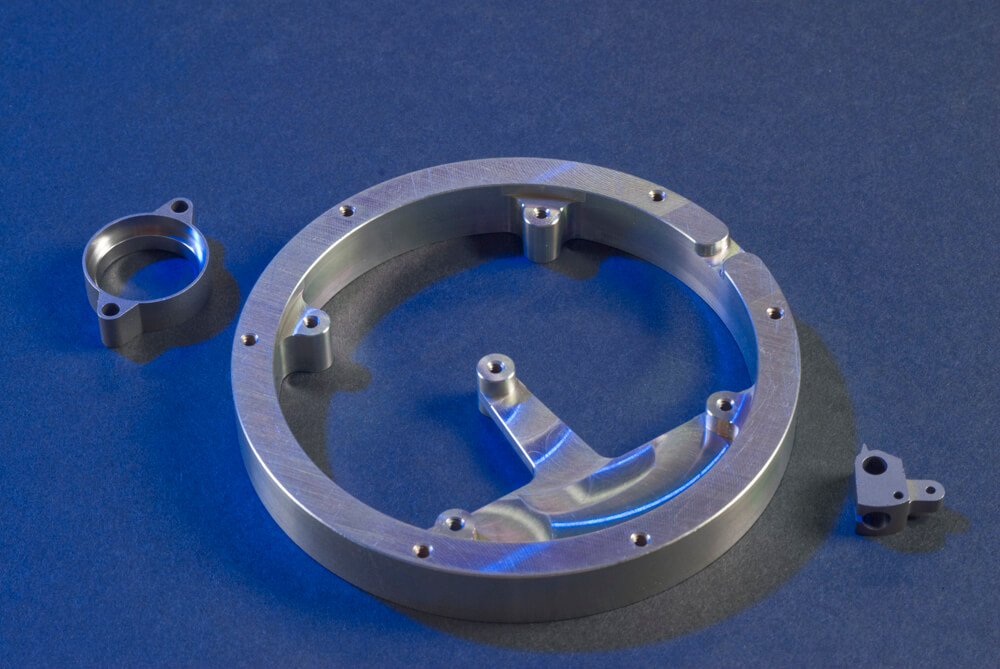

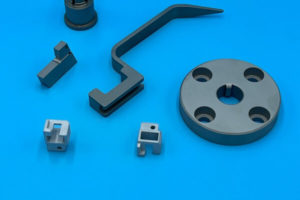

Our EDM machinery is invaluable for spaceflight as well, with existing customers in this field. We can provide the following components for use in or for servicing these systems:

- Launch ground support systems

- Missiles and missile defense systems

- Rocket engines and guidance systems

- Roving and space launch vehicles

- Satellites

- Space telescopes

The accuracy and consistency of our machines, added to the minimal recast layer, is a benefit of EDM over other traditional methods.

Advantages of Aerospace EDM

EDM processes mesh well with the industry’s needs in many ways:

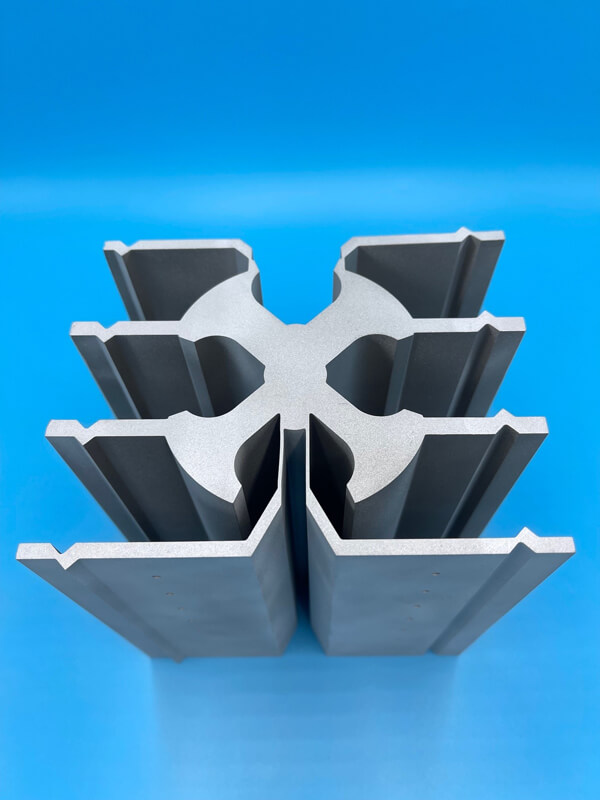

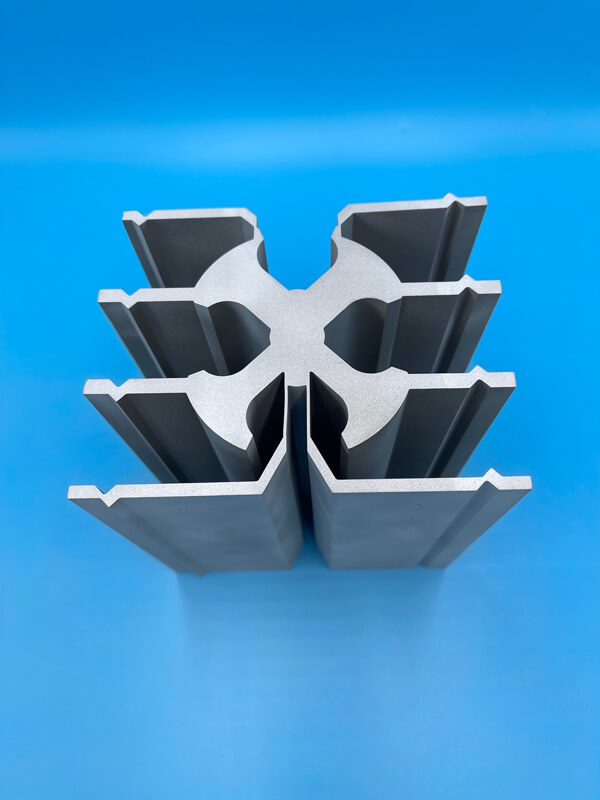

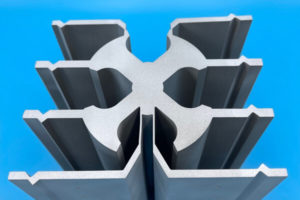

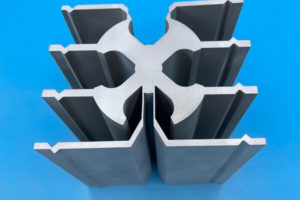

Cladding of alloys. The aerospace industry utilizes cladding with metals like aluminum, steel, and copper. The marriage of metals with dissimilar properties allows for the creation of a part that meets specific requirements, such as a particular strength or weight. Even after alloy cladding, EDM can cut these joined materials despite the differences in their structural properties.

Corrosion. Instead of oxygen, UV- and X-ray exposure can cause corrosion in some materials, particularly those found in moving aerospace components. Also, some of the metals commonly used experience chemical reactions when touching, resulting in galvanic corrosion. EDM reduces failure risks with its ability to accurately cut corrosion-resistant materials with ease.

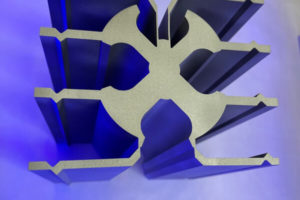

Elimination of broaching. EDM provides superior precision and a higher-quality finish, making a custom broach unnecessary.

Fast production and design iterations. Wire EDM does not typically necessitate tooling or delays during the creation of special tooling. With a fast program alteration, technicians can simply revise and create new iterations of designs.

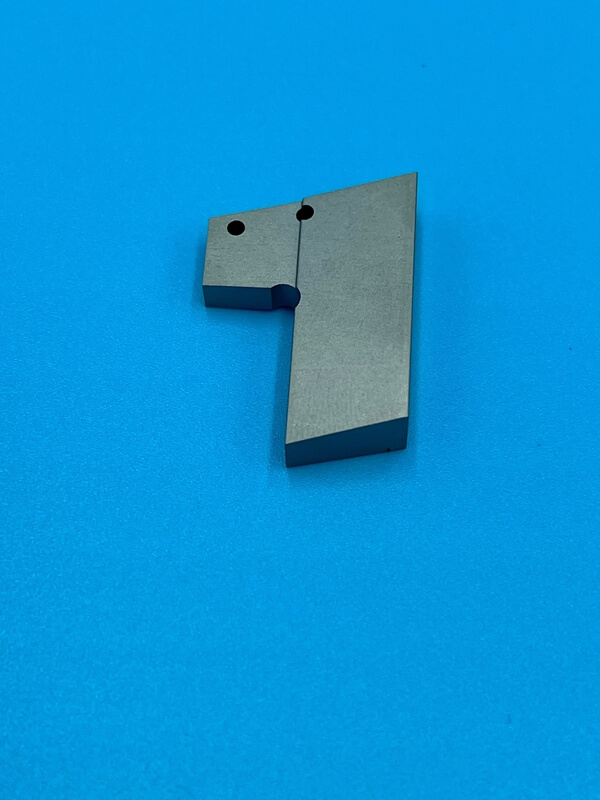

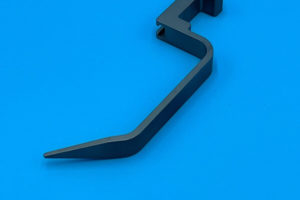

Finished surfaces. The EDM process excels in creating a smooth surface finish.

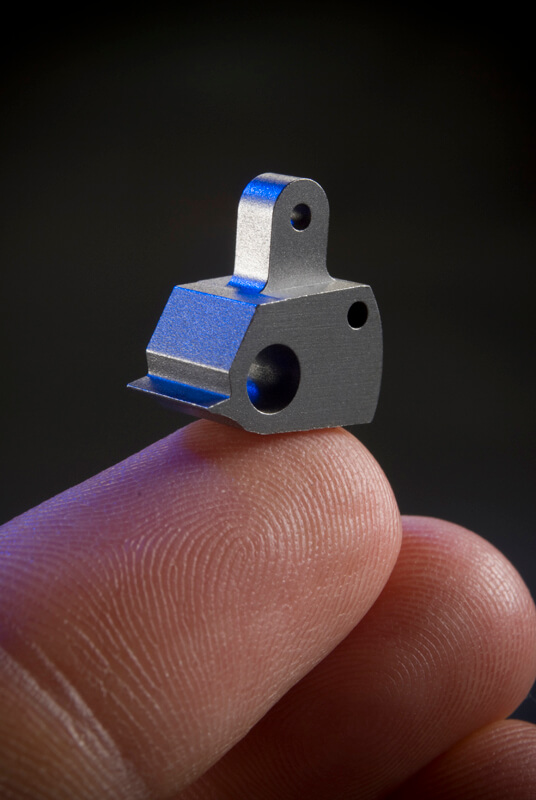

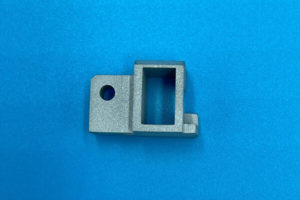

High precision. These smooth finishes prevent wear and subsequent leaks after cycling in aerospace components. EDM’s high precision also comes from the lack of cutter vibration, end-mill rubbing, or turning “rings” in tiny bores or deep cavities. Mechanisms like actuators and valves need this exactness to function well.

High strength. This industry needs durable materials that are strong yet flexible, such as Inconel and titanium. EDM machining can cut such metals without the usual limits of traditional machining.

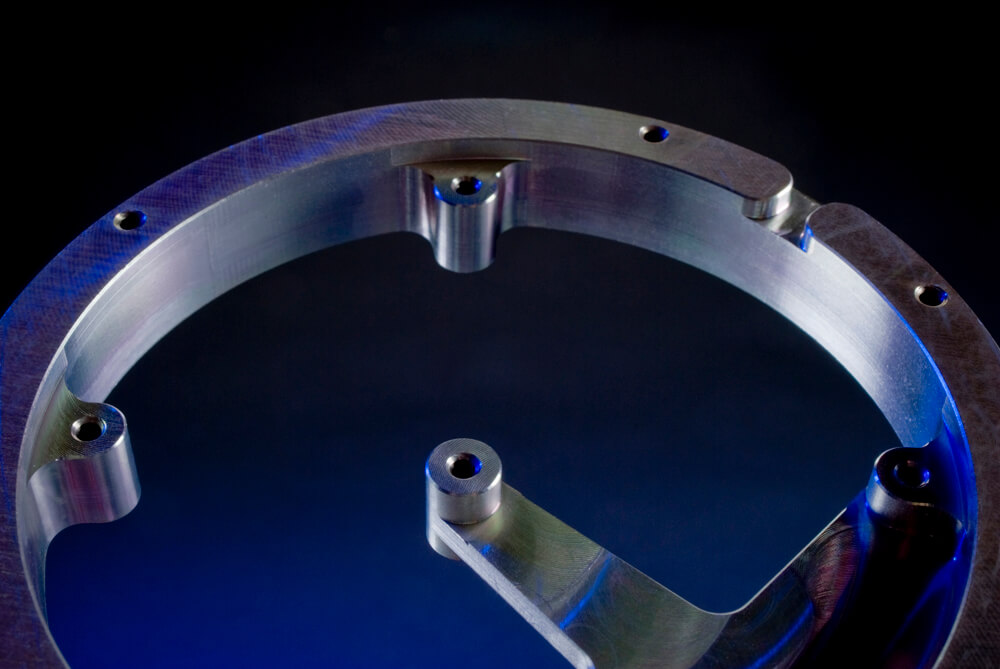

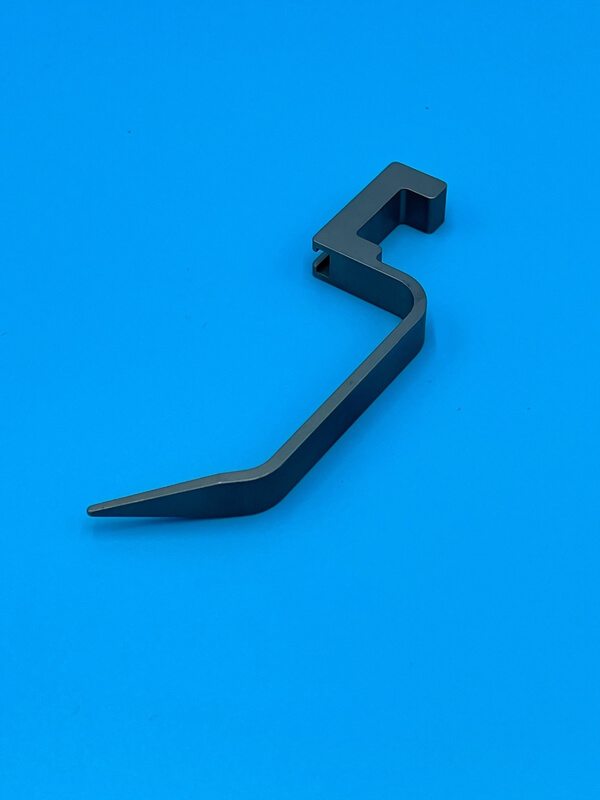

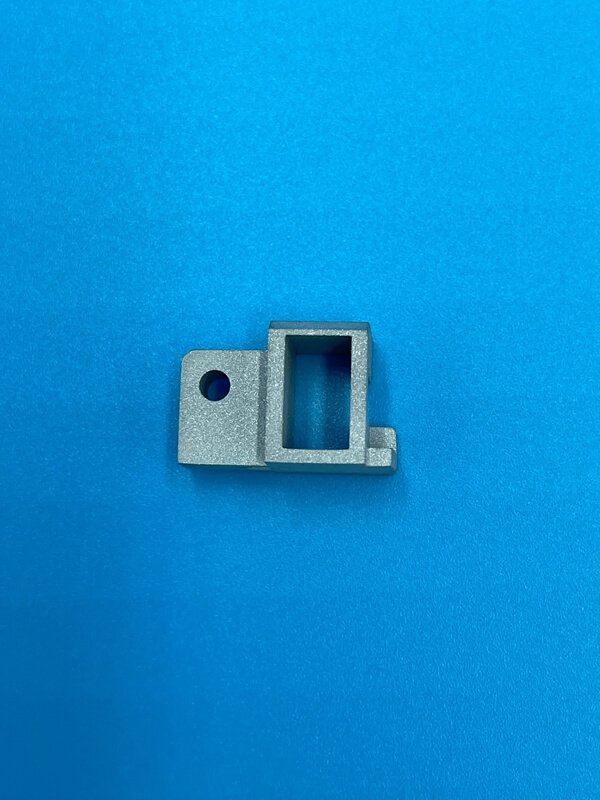

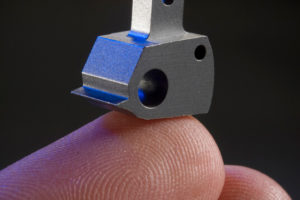

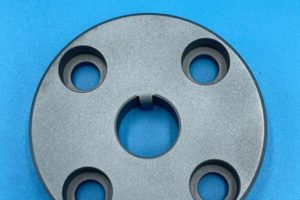

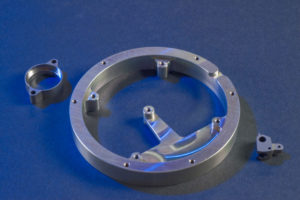

Size and weight. With a goal of reducing weight and space, many aerospace components are lightweight and small with intricate features. EDM easily handles thin-walled components, narrow slots, complicated geometries, and little corner radii.

Temperature and pressure fluctuations. Components for this industry must function in harsh environments with exposure to wide temperature and pressure ranges. A non-contact form of machining, EDM does not create stress on metal during manufacturing, unlike traditional methods that actually change a metal’s properties.

Experience in Wire and Sinker EDM of Aerospace Components

The aerospace industry relies on capable, industry-certified manufacturers. Since its start in 1989, New Jersey Precision Technologies has fabricated complex components with precise EDM methods for most major commercial, private, and defense companies in the aerospace sector. We are also proud to serve our clients in the U.S. government and military, supporting our troops on land, sea, and air through major aerospace defense contractor programs and our Mil-Spec products.

Providing short lead times, our 24/7 operation consists of dozens of CNC machines, over 40 EDM machines, and automated inspection systems. Our EDM department has advanced Mitsubishi wire and sinker equipment producing components of up to 6,000 pounds at dimensions of 50-plus inches by 20 inches thick. Wire and sinker EDM equipment can hold tolerances of approximately 0.0001 and 0.0002 inches, respectively.

Our talented technicians and EDM capabilities make us the superior choice in precision components and Wire & Sinker EDM services for the aerospace industry. Contact us or request a quote to learn more about our work in this field.